- Midland Basin

- Delaware Basin

- HSER

- Case Study

| Pipeline |

|

|

| Storage |

|

|

| Recycling |

|

|

| Disposal |

|

|

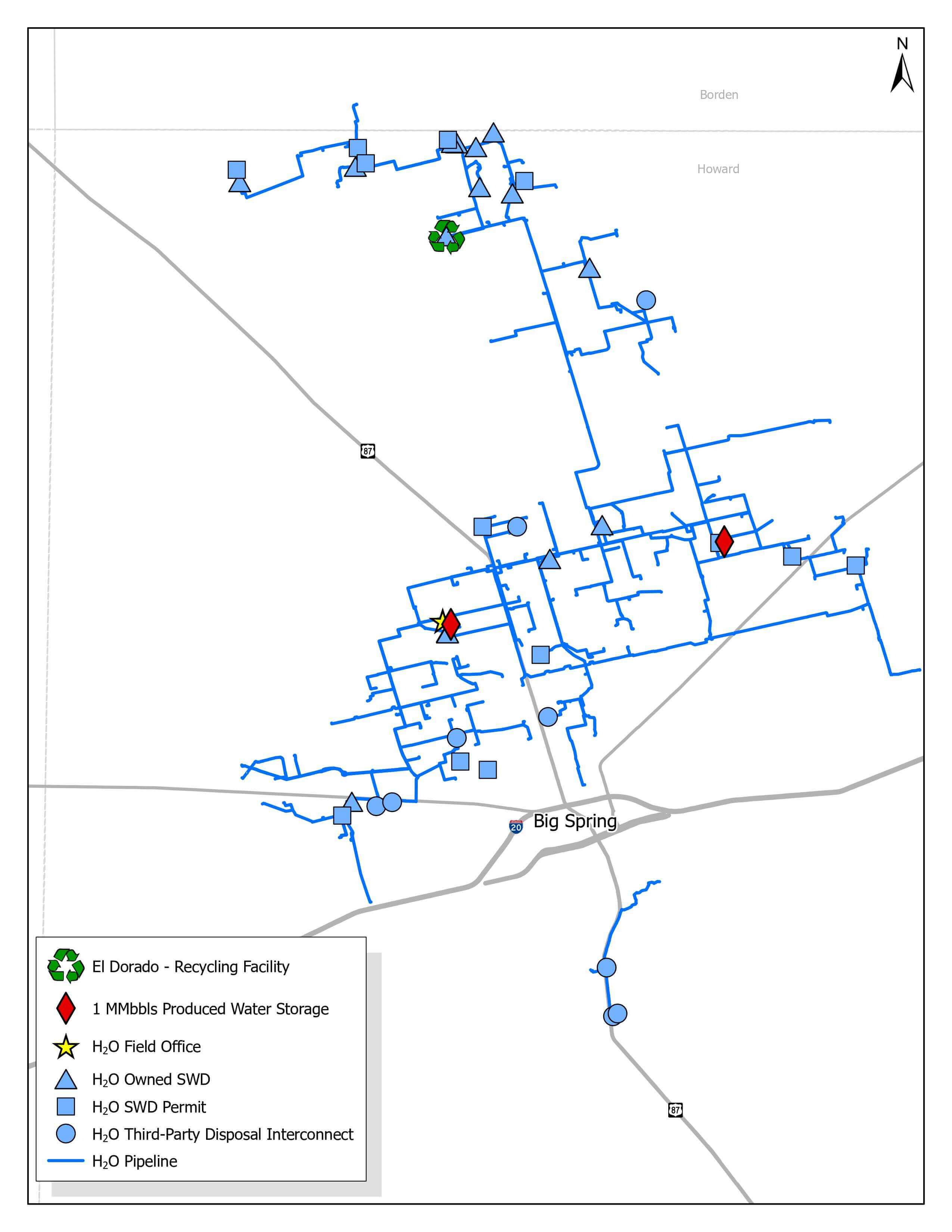

| All facilities are 100% interconnected via permanent pipeline. | ||

Gathering

Our footprint and interconnectivity with multiple third parties provides us with tremendous optionality and allows produced water to be transported (or “wheeled”) to the highest value market, overcoming bottlenecks which might necessitate disposal in a constrained area. We have also facilitated “transportation swaps” on behalf of our customers, where they have the ability to deliver water in one location on our system and receive it back in another. Transportation swaps can be combined with storage to provide re-delivery at a later date when the water can be more efficiently used for hydraulically fracturing operations. By giving producers access to all of these options, we are able to maximize capacity utilization across our system and pass the cost savings on to our customers.

In addition to enabling safe, reliable and cost-effective operations, our pipeline system has eliminated over 1.3 million truckloads of produced water, preventing over 100,000 metric tons (MT) of CO2 emissions.

Storage

Benefits of integrated storage across the system includes:

- Peak Flow Management – during the early stages of well flowback when volumes are materially higher than long term average production rates, avoiding the need for additional disposal capacity or trucking

- System Reliability – in the event a disposal well or recycling facility is down due to planned maintenance or an unforeseen event such as a power outage, or unplanned maintenance

- Hydraulic Relief – in the event volumes are gathered or re-delivered to locations across the system that would be otherwise hydraulically constrained, eliminating the need for additional disposal, larger size pipe, or trucking

- Recycling – to be used as a staging area to facilitate recycling rates of up to 100%

- Banking – where producers are able to store or “bank” their produced water for use in a hydraulic fracturing operation at a later date

Recycling

We offer two primary recycled water qualities to our customers:

- Raw water skimmed and free of hydrocarbons,

- A clean brine treated to the producer’s specification.

Our customers can access treated produced water at our storage hubs or off our pipeline via mobile treatment (treatment on the fly) options across our network. Our logistics capability plus flexibility in treatment options gives us the ability to find the best solution for each of customer.

H2O Midstream is targeting to deliver >40% of its total gathered volume back to customers for oilfield fracking operations over the next 24 months.

Disposal

Long-Term Beneficial Use

The oilfield water industry stands uniquely poised to be water positive thru investment in the right infrastructure that aggregates and allocates water to its highest and best value use cases. We are actively involved with industry organizations to advance these and other sustainable use cases, thru participation in industry organizations, and supporting those seeking to reduce the barriers to entry for these new markets through research and advocacy.

H2O Midstream Memberships to Advance Sustainable and Beneficial Use:

- Texas Produced Water Consortium

- Oilfield Water Stewardship Council (B3)

- UTPB (University of Texas Permian Basin) Texas Water Energy Institute Board Member